The Platinum process begins with the mixing of chemicals (such as Sodium Palladate). Directly afterwards – they are brushed onto watercolor paper. The paper is made in Italy, and is pure cotton for a minimum chemical reaction with the Platinum. The brush is a very soft hake, that will not scratch the paper.

The paper is dried – but kept humid. for best results, the paper should be used soon after coating. Even 24 hours has an effect on the outcome.

The Negative needed for palladium tends to be be darker. Pyrogallol developer is used on film negatives to improve the density and acutance of negatives used for the Palladium and Platinum Processes.

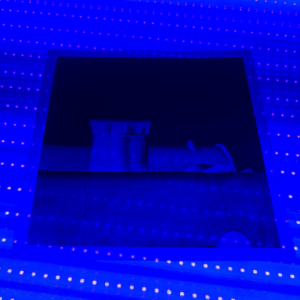

This custom light table creates an even illumination of ultra-violet rays that expose the palladium. Normal light will not develop platinum or pallidum prints.

After exposure, the paper shows a ‘ghost’.

With training, you can recognize the correct level of exposure by a glimpse at the ghost.

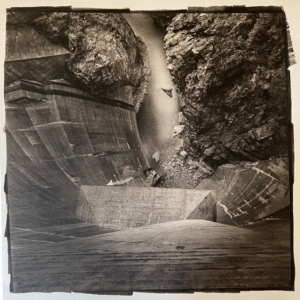

A final print in 12″ x 12″. Shows the beautiful ranges and details of a Palladium print. Most of the prints are almost completely Palladium as it develops deeper and warmer black tones.

A Smaller 3 ” x 3″ print.